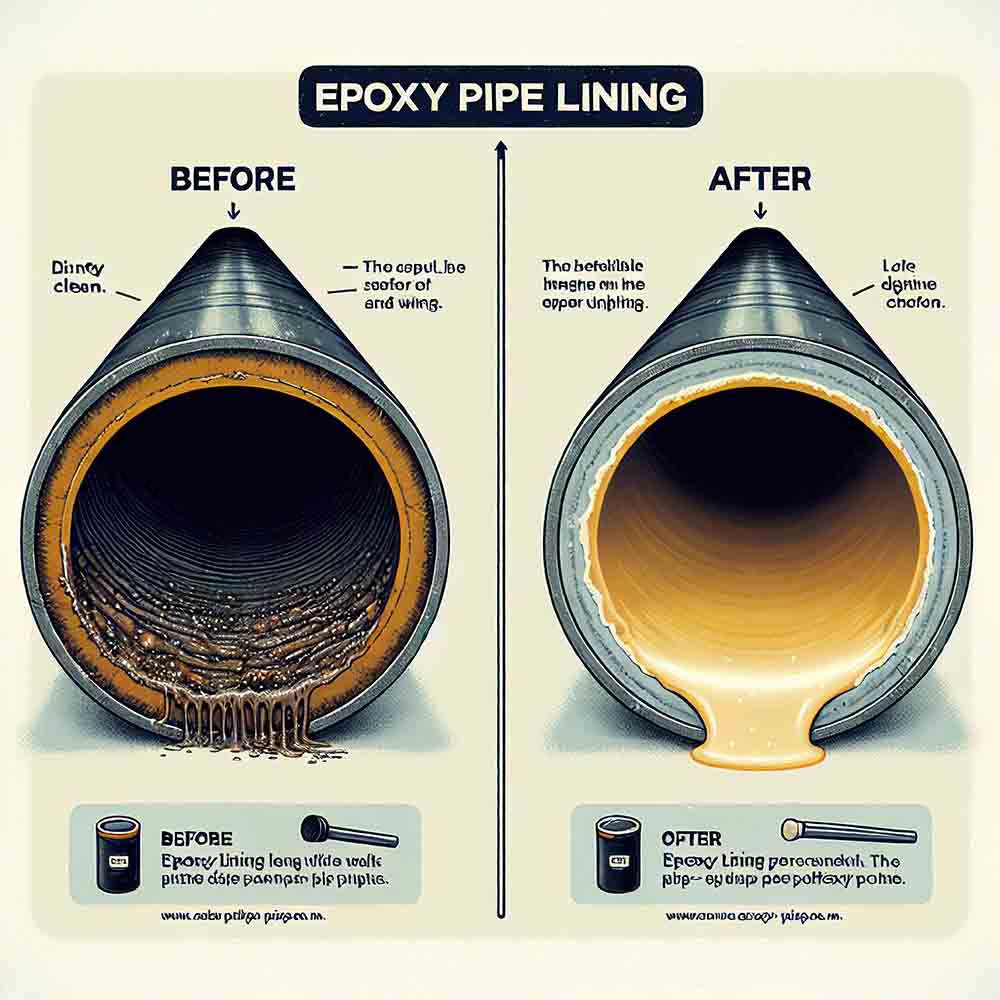

Epoxy lining has changed the way damaged pipes are restored, offering a durable alternative to full-scale replacement. While the process looks straightforward from the outside, inside the pipe, a series of chemical and physical transformations create a seamless new interior surface. This method is a key component of trenchless pipe lining in San Diego, CA, where aging infrastructure and soil conditions make non-invasive solutions especially valuable for long-term pipe rehabilitation.

The First Stage: Preparing the Surface

Pipes undergoing epoxy pipe lining need a clean slate before the resin is applied. Any buildup, corrosion, or debris left behind could interfere with adhesion, so technicians use high-pressure air, abrasive cleaning tools, or mechanical brushing to remove obstructions. This step exposes the pipe’s original surface, making it more receptive to the epoxy.

The Coating Process: Spreading and Curing

Once the pipe is prepped, the liquid epoxy is introduced, often using air pressure or a rotating application method. The material spreads evenly, flowing into small cracks and imperfections. As it settles, the epoxy begins to transition from a viscous liquid into a hardened, protective layer. The curing phase of any trenchless sewer repair project is critical—temperature and humidity affect the speed and strength of this transformation. Some applications involve heated air or specialized catalysts to accelerate the process and optimize the final product.

The Molecular Shift: From Liquid to Solid

At the microscopic level, epoxy undergoes a chemical reaction known as polymerization. Individual resin molecules, triggered by a curing agent, link together to form long, interwoven chains. This shift locks the material into place, creating a structure that resists water intrusion, pressure fluctuations, and common corrosive elements. Unlike temporary patchwork solutions, this trenchless pipe replacement process results in a uniform lining that strengthens the entire pipe.

A Reinforced Pathway for Flow

After curing is complete, the newly lined pipe behaves like a modernized conduit. The smooth, non-porous surface improves water flow by reducing friction and buildup. Rust, mineral deposits, and weak spots become non-issues, preventing complications that often contribute to clogged drains. This enhanced efficiency extends the pipe’s functionality without disrupting the surrounding property.

Epoxy lining transforms aging pipes into durable, efficient systems without the mess of traditional repairs. By transforming the interior structure at a molecular level, this method reinforces pipelines with an added layer of durability and performance. Whether you’re considering trenchless pipe replacement or a more targeted solution, our experts can help. Contact us today to learn how epoxy lining can extend the life of your pipes.

Contact Our Trusted Team Today

Home and business owners can trust Perry Plumbing and Pipelining to deliver A+ service each and every time. Contact a plumber from our highly dedicated team today to schedule your appointment!