What is Pipelining

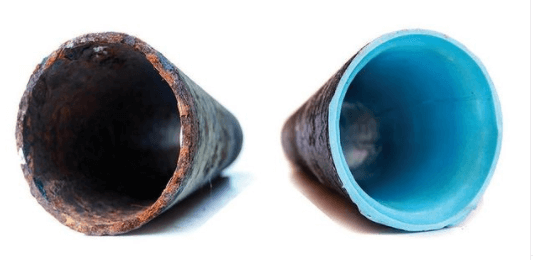

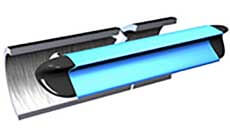

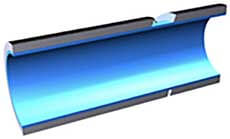

To best describe pipelining and sewer pipe replacement, imagine a smooth new PVC pipe installed within the existing damaged pipe. Afterward, the separation between the old & new pipes is filled with epoxy, a watertight seal. As a result, tests show an improvement of over 100% in original flow capacity despite the loss of inner diameter.

Sewer pipelining is a process used for repairing and replacing cracked, leaking, backed up and damaged sewer lines. It is also used to even-out or smooth rough bends and joints. As a result of it being a “no-dig” system, costly excavation and demolition are no longer necessary. So, pipelining is often less expensive than the traditional re-piping alternatives, such as excavations or open trench methods. Using a “no dig” trenchless process to avoid yard excavation, sidewalk destruction or digging up trees, sewer lining involves inserting new epoxy-saturated pipe tubing into existing pipes, inflating the tubing and curing it into place with hot air, steam or bluelight LED technology. This results in a new seal lining the walls of existing pipes, replacing broken piping with the potential to last for decades. It involves a four-step process and it is substantially putting a pipe within a pipe. Lining is cost efficient and less disruptive than replacing the entire pipe. Pipe lining also increases the life of a piping system, preserves the building structure and landscape, and causes little to no destruction to the property.

The most common words and phrases often used interchangeably with the sewer pipelining and sewer pipe replacement process include epoxy pipelining, sewer pipelining, cured-in-place pipelining (CIPP Lining), UV sewer lining (known as ultraviolet cured-in-place pipelining), lateral sewer line, sewer relining, internal pipelining, drain pipelining, internal pipelining, no dig sewer relining.

Steps to completing the pipelining process:

Why is pipelining better?

Trenchless pipelining and sewer pipe replacement repair is a less invasive solution for replacing pipes, as it doesn’t require excavation or tearing up yards, trees, driveways or sidewalks or the need to stop traffic during work. This method also eliminates the need to repave after the replacement is complete, making money savings significant. With this technology, underground utilities can be spared the risk of damage. This method targets root intrusion and helps reduce erosion of pipes and improves the flow of pipes.

How do I know if I need pipelining?

When you own or manage a building over 10 years old, the damage is probably already in progress. Undoubtedly, you’ll experience or see symptoms of pipe corrosion. Overall, symptoms can include the following:

What type of pipes can be lined?

Both residential & commercial sewer laterals & drainage pipes from the property to the main line can have lining done to them. In addition, roof drainage pipes, collectors, & commercial floor drainage pipes can also have this done to them.

Why do pipes fail?

Two common reasons why pipe fail are corrosion and tree roots growing into the pipe.

Oxygen, metal, water and minerals deterioration cause pipe corrosion. This chemical reaction causes a buildup called scaling, which is a pile of corrosion where minerals like chloride and Sulphur turn into acids that eat away the pipe. Pouring chlorine into pipes causes corrosion over time. Tree roots also cause pipe failures. Their roots get into pipes looking for water, causing cracks in the pipes. Unquestionably, metal plumbing systems using copper or other galvanized systems show significant problems through time. Moreover, problems can occur in as little as 6 years. In addition, most copper & galvanized pipes show signs of corrosion within 10 years. So, the best long-term solution to pipe corrosion is to stop the water from coming into contact with your pipe’s walls.

Origins of trenchless pipelining

Pipe replacing used to involve excavation of yards, tearing up driveways and sidewalks, removing trees and ripping up gardens. Plumbing companies started using a process called sliplining, developing other pipe bursting methods and eventually started using pipelining.

The premiere solution for mechanical pipe repair system rehabilitation.

NuFlow has the unique ability to fix piping systems using existing access points and it offers the most viable and least disruptive option for pipe repair, pipe renewal and trench-less sewer repair.

Steps to Nu Flow™ Pipelining

1. Identify the problem

A camera is used to identify where the clog is.

2. Clean the pipes

The first step is to clean out all roots by jetting the lines or using pneumatic tools.

3. Install the liner

Epoxy is poured into a liner that is pulled in place and then inflated to rebuild the pipe’s structure.

4. Inspect

A camera is used to make sure the pipe has been fixed.

Contact Our Trusted Team Today

Home and business owners can trust Perry Plumbing and Pipelining to deliver A+ service each and every time. Contact a plumber from our highly dedicated team today to schedule your appointment!